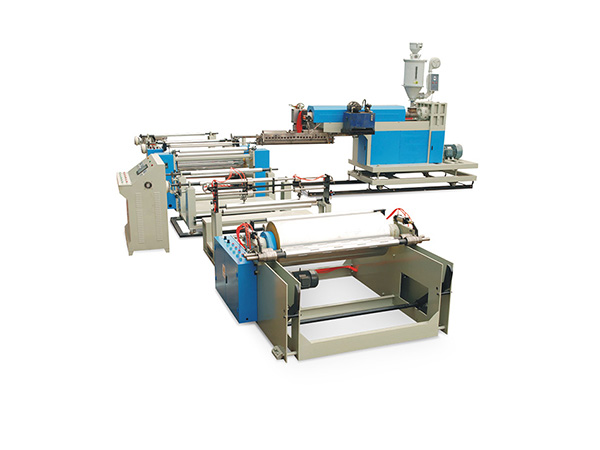

The machine can compound EPE, PU, EVA, XPE and sponge together with plastic film, kraft paper, aluminum film and non-woven fabric. After melting at high temperature, the plastic particles are evenly coated between the plastic sheet and the plastic film after extrusion, and then extruded by the flower roller. The surface patterns of the products are uniform and clear, the three-dimensional sense is strong, and the product rate is high, which is loved by customers at home and abroad.

technical parameter:

|

機(jī)械規(guī)格 |

900 |

1100 |

1300 |

1700 |

|

最大有效寬度 |

800mm |

1000mm |

1200mm |

1600mm |

|

擠出螺桿直徑 |

Φ80mm |

Φ90mm |

Φ90mm |

Φ100mm |

|

最大擠出量 |

160kg/hr |

180kg/hr |

220kg/hr |

240kg/hr |

|

擠出機(jī)總功率 |

30KW |

30kw |

37KW |

45KW |

|

涂膜最高速度 |

80-150m/min、 |

|||

|

適用涂膜樹(shù)脂 |

LDPE、PP、 EVA 、EAA |

|||

|

適用基材 |

BOPP、BOPET、BOPA、CPP、CPE、紙張(PAPER)、鋁箱(AL)、無(wú)紡布(NONWOVEN) |

|||

|

涂膜厚度 |

0.012~0.05mm |

|||

|

凈膜厚度誤差 |

≦±5% |

|||

|

復(fù)合冷輥 |

|

|

|

|

|

主放卷直徑 |

Φ1500mm(特大卷徑) |

|||

|

輔助放卷直徑 |

Φ450-600mm |

|||

|

收卷直徑 |

Φ1200mm(特大卷徑) |

|||